- Control Valve

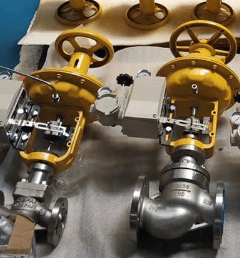

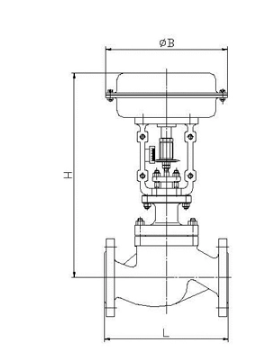

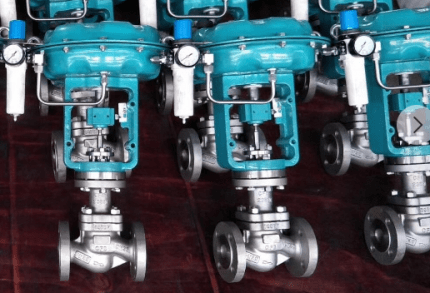

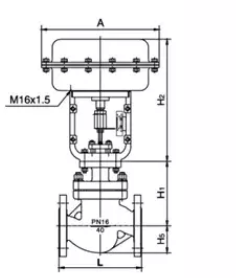

- Pneumatic Control Valve

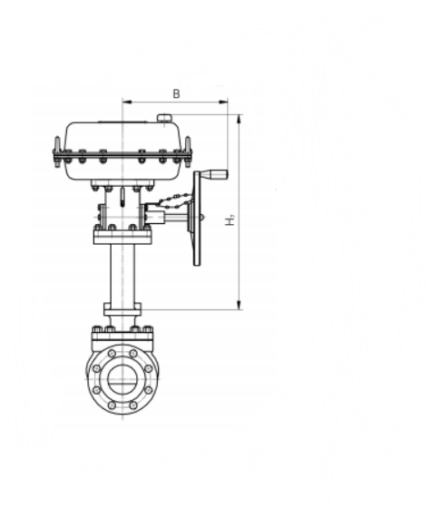

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

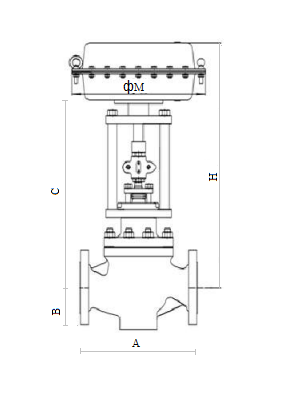

- Pneumatic Double Seat Control Valve

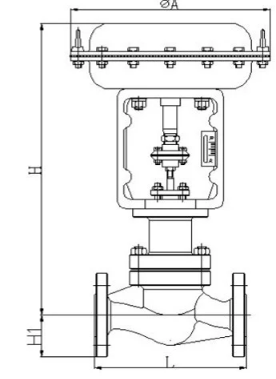

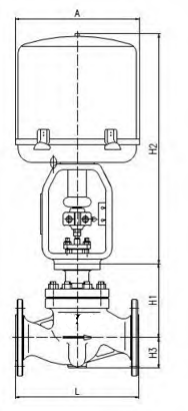

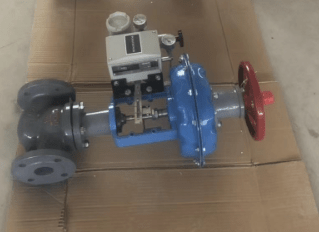

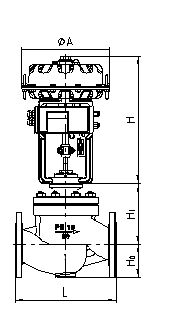

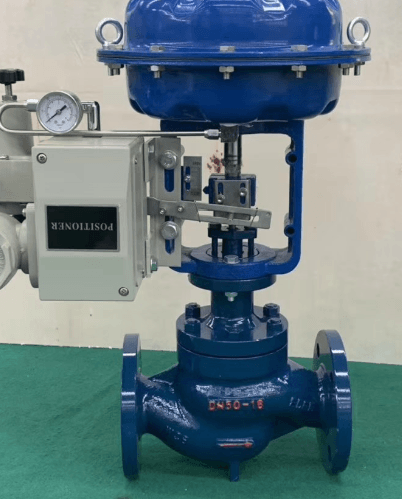

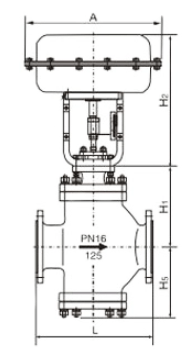

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

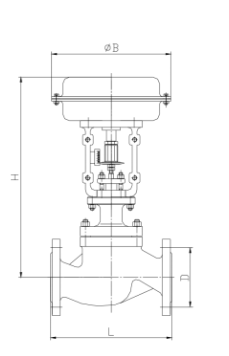

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

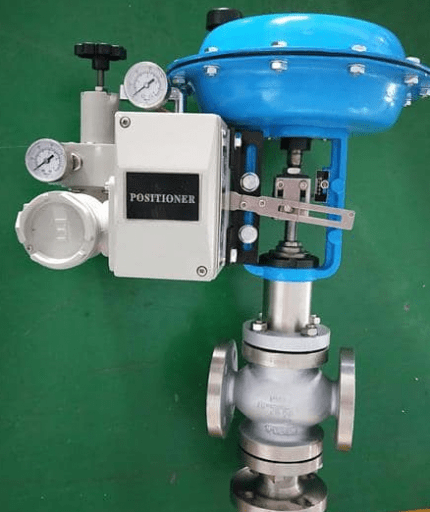

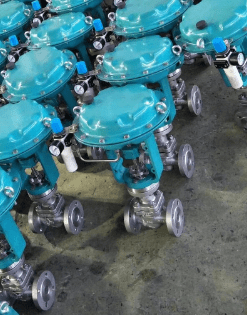

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

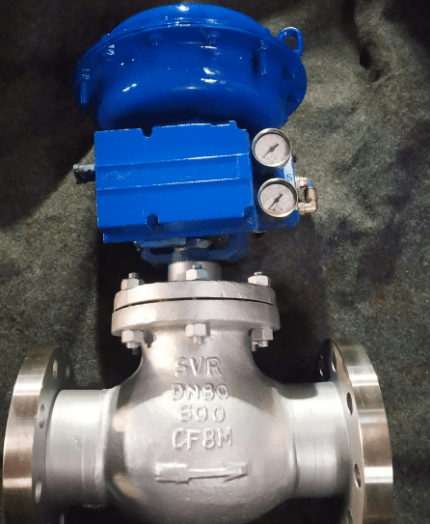

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

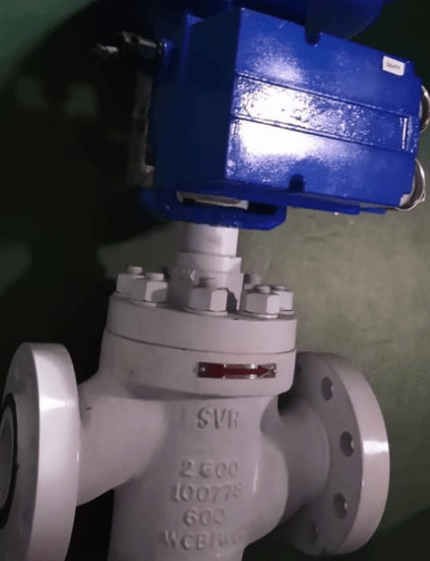

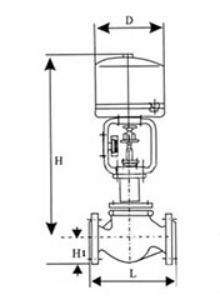

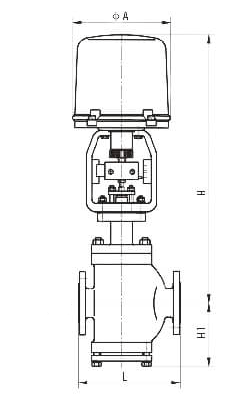

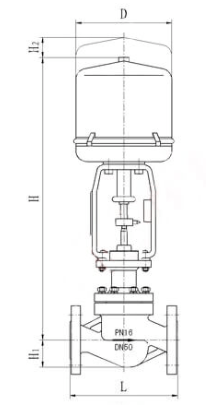

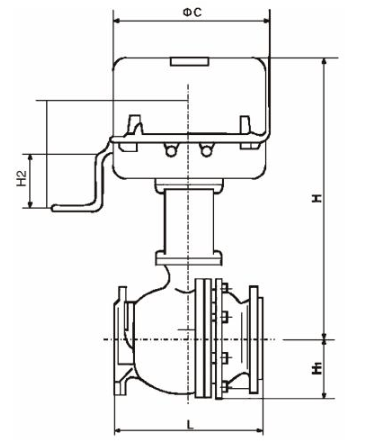

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser Valve

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

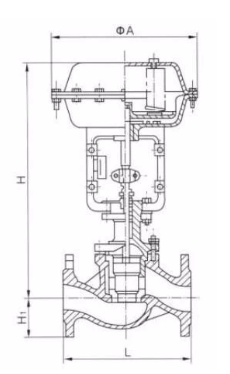

Control Valve Suppliers in UAE: Ensuring Efficient Flow Management

Middleeast valve is one of the best Control Valve Suppliers in UAE. Control valves play a critical role in regulating fluid flow, pressure, and temperature across various systems. In industries such as oil and gas, manufacturing, and water treatment, control valves ensure precision, safety, and efficiency.

What is a Control Valve?

Control valves are vital components in fluid control systems. They regulate the flow of fluids—such as gas, steam, or liquid—through pipes by adjusting the valve position according to a signal received from a controller.

How Do Control Valves Work?

Control valves function by receiving signals from a controller that determines how open or closed the valve should be to maintain the desired flow rate, pressure, or temperature. The valve’s actuator responds to the control signal and adjusts the valve’s position accordingly, allowing precise flow control.

Functions and Benefits: 1)Flow Regulation: Ensures consistent fluid delivery. Types: 1)Three way control valve Industries Served: In the UAE, control valves are indispensable in sectors such as: 1)Oil and Gas Industry Description: Available Materials: Ductile Iron, Cast iron (WCB, WCC, WC6) LCC, LCB, Stainless Steel (SS316, SS304), Super Duplex (F51, F53, F55) Electric Actuator details: 1)Torque – 3 – 9 nm Configuration of a Pneumatic Actuator: 1)4-20 amp Temperature: 1)Standard -4°F to 200°F (-20°C to 93°C)

2)Pressure Management: Maintains system stability.

3)Safety Assurance: Helps prevent system overloads or failures.

4)Durability: High-quality materials ensure long-lasting performance even under extreme conditions.

2)Cage type control valve

3)Double seat control valve

4)Type shutoff control valve

5)Single Seat control valve

6)Water Control valve

7)Globe Control valve

8)Angle type control valve

2)Pipeline Industry

3)Marine Industry

4)Power Industry

5)Nuclear Industry

6)Mining Industry

7)Chemical Industry

8)Petrochemical Industry

9)Steam Services Industry

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Medium: Air, Water, Chemical, Steam, Oil

Operations: Electric actuated and Pneumatic actuated

Size: 1/2”- 24”

Ends: Flanged, butt weld, socket weld, threaded

2)Operating pressure- 8 Bar

3)Port Connection-NPT1.4”

4)Mounting Base-ISO5211

5)Temperature–20°C – +80°C

2)Pneumatic single acting actuators

3)Pneumatic double acting actuators

4)Pneumatic rotary actuators

5)Pneumatic Scotch and Yoke actuators

6)Pressure: 228 bar

2)Low -40°F to 176°F (-40°C to 80°C)

3)High 0°F to 300°F (-18°C to 149°C)